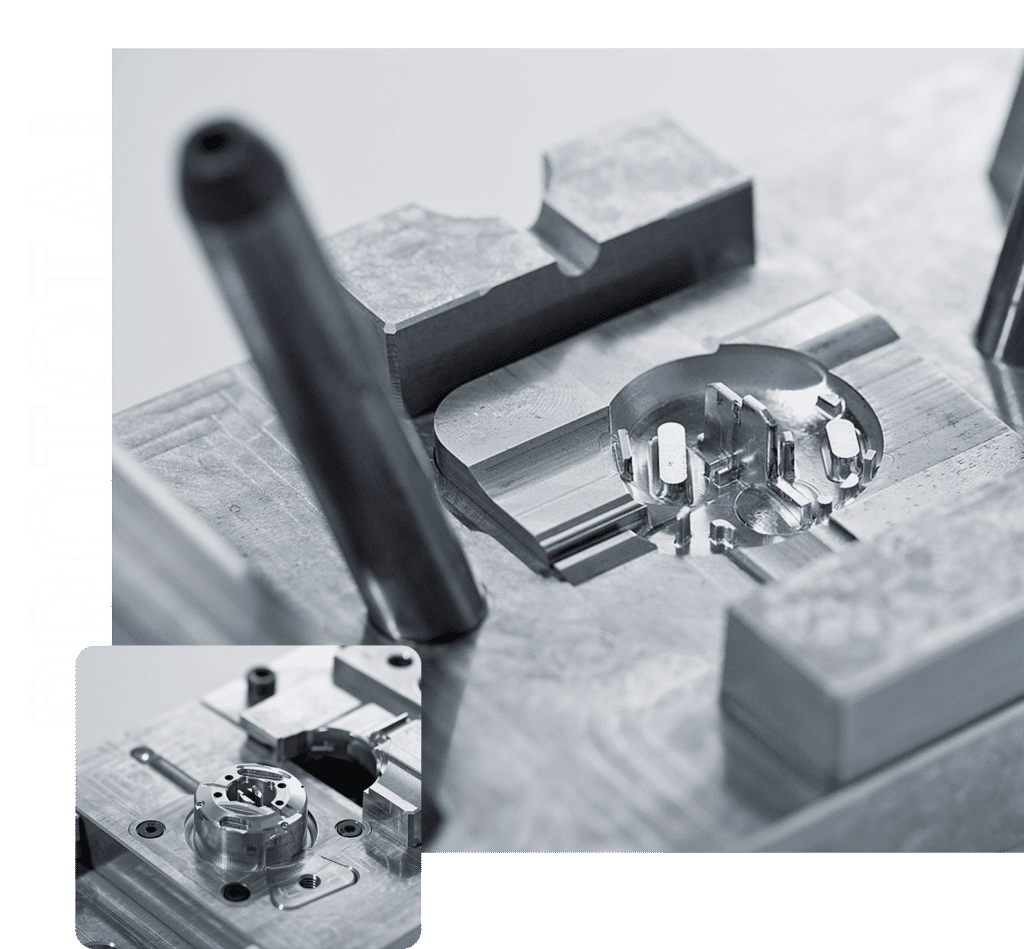

The tools are tailored precisely to your requirements. This can include various types of inlets, such as edge, rod, snout, tunnel, film, or hot runner. The tool surfaces can be grinded, polished, blasted, spark-eroded, or etched to achieve the perfect texture for your injection-molded parts. We also offer overmolding tools and true 2K tools when the components need to consist of different materials.

Finally, the tools are assembled, and a test run is conducted to ensure their correctness. Afterward, the trial injection moulding in our injection moulding machines can commence.

Tool design is simplified as much as possible to meet the number of components to be manufactured. Manufacturing takes place internally within the group, and the tools are made of aluminium, ensuring a fast and efficient production process and keeping investment costs as low as possible. In the tool, components can then be injection-moulded under production-realistic conditions. Typically, around 100 components are manufactured.

The tool design is adapted for a more automated injection moulding process. Manufacturing is carried out internally within the group, and the tools are made of aluminium, ensuring a fast and efficient production process and keeping investment costs as low as possible. In the tool, components can then be injection-moulded under production-realistic conditions. The tool’s lifespan is up to 100,000 shots, which covers the lifespan of a significant number of components.

The tools are made of steel and are purchased from external tool suppliers. At each step of the process, our project team monitors schedules to ensure smooth operation from start to finish. This includes everything from tool design approval to the measurement of trial samples and tool adjustments. Efficient management is ensured by conducting all manufacturing in accordance with our tooling standards. Our project team then handles the retrieval of tools for the production of final trial samples at our own site.

Want to see what materials we have to offer as a Group across Europe?

Download our 3D Printed Guideline sheet below.

For more detailed data sheets, please visit the appropriate pages.

The main difference between aluminum tools and steel tools lies in their tool lifespan. Aluminum tools are lighter and can be machined faster in our milling machines, often offering cost advantages. They are ideal for producing prototypes and small volumes. Aluminum also has good heat conductivity, allowing for more even temperature distribution in the mold. The downside of aluminum is that it’s a softer material and wears out more quickly, especially with glass-fiber-filled materials.

Steel tools have higher durability and resistance to wear. They are ideal for large-volume production and for injection molding with materials containing a high level of glass fiber or high-temperature materials. Steel tools can withstand higher pressures and temperatures during the injection molding process and have a longer lifespan compared to aluminum tools. The downside of steel tools is that they take longer to manufacture, often come with a higher cost, and are larger and heavier.

The choice between aluminium tools and steel tools depends on specific needs and requirements for the manufacturing process. If the volume is low, and the lead time is short, aluminium tools can be a suitable choice.

On the other hand, if high volume and durability are crucial, steel tools are typically the preferred option.

Do you need assistance or guidance in choosing the type of tool you require? We can help! At Prototal, we have extensive experience with tools and are happy to guide you to the right choice.