And when AM is combined with injection moulding (IM), the results can change the entire approach to manufacturing. That’s exactly what happened at the Swedish site with their collaboration with Sensorbee, a Swedish pioneer in smart, solar-powered air quality sensors.

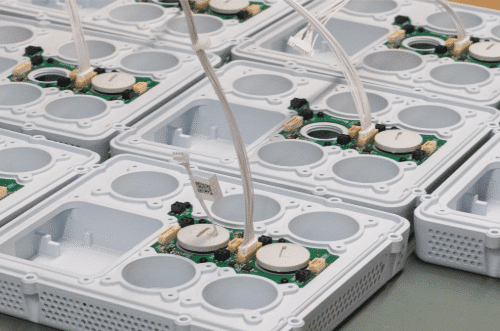

Sensorbee, based in Linköping, develops outdoor sensors for environmental monitoring that are used in smart cities, construction sites, ports and industrial areas. These compact, solar-powered devices connect via mobile networks and send real-time data to a cloud platform, enabling data-driven decisions to reduce air pollution.

Their latest sensor is the third generation in development – a product shaped by learnings, iteration and innovation.

Sensorbee needed to quickly launch a product that was:

These requirements led to the conclusion that traditional manufacturing was not enough. That’s where Prototal came into the picture.

We worked closely with Sensorbee to develop a manufacturing strategy that suited their needs. The result was the best of both worlds: additive manufacturing and injection moulding.

Fast Start with AM We started by 3D printing the lid and base with advanced materials and finished the surfaces with vapour smoothing, creating weatherproof and UV-resistant product parts.

This allowed Sensorbee to:

When Sensorbee wants to scale up to significantly higher volumes, they can quickly switch to injection moulding for the base part – in-house at Prototal – which lowers unit costs and enables volume production. The caps, with their complex geometries, will continue to be 3D printed, giving Sensorbee the flexibility to update designs and customise configurations.

“We’ve been able to keep batch sizes small, get fast deliveries, and avoid large inventories. That flexibility has really helped us keep costs at reasonable levels.” – David Löwenbrand, Sensorbee

Industrial 3D printing enabled Sensorbee to go from prototype to production in weeks, instead of months.

Additive manufacturing and post-processing enabled compact, waterproof, and sensor-tight devices – difficult or impossible to manufacture using traditional methods.

“We are now doing things in very small spaces that were previously much larger – like shielding temperature sensors from solar radiation in a compact double-layer design.” – David Löwenbrand, Sensorbee

Injection moulding will continue to ensure low unit costs in volume production, while AM remains the best choice for custom and complex parts.

Sensorbee’s collaboration with Prototal shows how the right choice of manufacturing method leads to smarter and faster product development. With our ability to seamlessly switch between technologies and quickly adapt to your needs, we are your partner for production – from one to a million parts.

“Prototal has been a fantastic partner. Their approach has helped us move quickly and maintain high quality – and we look forward to growing with them in the future.” – David Löwenbrand, CTO and co-founder, Sensorbee

Whether you’re launching a new start-up product or improving a large-scale production solution, Prototal combines speed, scale, and flexibility – all under one roof.

Contact us today to see how we can help support you on your next project.